40 Years of International Expertise

Selectrode Industries

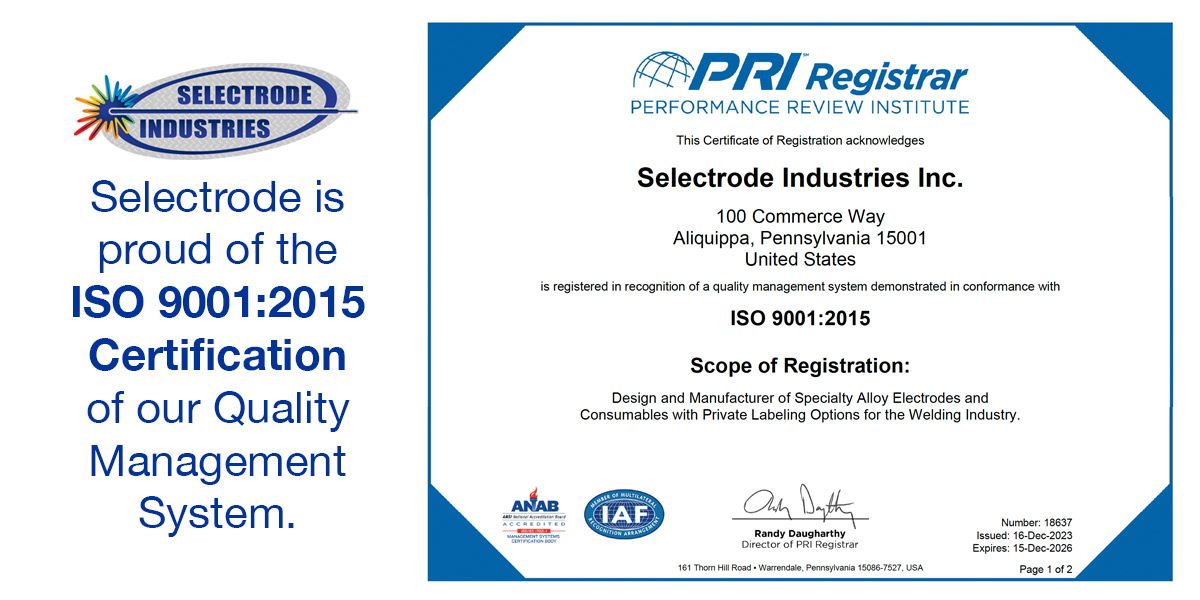

For over 40 years Selectrode has been the market leader for private label welding electrodes, accessories, brazing, and mig and tig alloys. In fact, Selectrode is the first and still the only manufacturer that does not sell its own brand. Our goal is to supply and support our customers, not compete with them. Our mission is simple, produce a huge selection of the highest quality welding consumables, package them in our custom high quality packaging, and sell them at competitive manufacturer direct wholesale prices.

For over 40 years Selectrode has been the market leader for private label welding electrodes, accessories, brazing, and mig and tig alloys. In fact, Selectrode is the first and still the only manufacturer that does not sell its own brand. Our goal is to supply and support our customers, not compete with them. Our mission is simple, produce a huge selection of the highest quality welding consumables, package them in our custom high quality packaging, and sell them at competitive manufacturer direct wholesale prices.

Available Products

Selectrode can provide virtually any electrode, brazing alloy, mig wire, tig wire, flux, powder spray torch, wear plate, or accessory available on the market.

If we don’t offer it, our research and development team will work with you to develop any custom product in the color and alloy chemistry you desire.

SELECTRODE is your ONE STOP for CUSTOM WELDING ALLOYS

Selectrode Industries believes we produce the finest versions of every available product in the market, however if you currently have a specific product in your offering that you would like us to replicate and or enhance, this is an easy goal for us to achieve. Our R&D department can rapidly accomplish this task and enable you to purchase this custom product in single production run quantities for each diameter. We also will sell our formulations in concentrate form to manufacturers, or coat your wire in house with our formulations.

Selectrode Industries believes we produce the finest versions of every available product in the market, however if you currently have a specific product in your offering that you would like us to replicate and or enhance, this is an easy goal for us to achieve. Our R&D department can rapidly accomplish this task and enable you to purchase this custom product in single production run quantities for each diameter. We also will sell our formulations in concentrate form to manufacturers, or coat your wire in house with our formulations.

Private Branding

Our special services include:

One, two or three lines of imprint can be applied clearly to your product providing both technical and marketing information.

Selectrode Industries can customize most of the products we produce in an array of colors (other than graphitic based electrodes) to make your product line unique in the marketplace. The available colors are limitless and can be purchased in single production run quantities for each diameter.

The Selectrode marketing concept makes it extremely easy for resellers to purchase the very best versions of private branded alloys in the categories below:

Click on a Category for Information & Data Sheets, or View All Products.

Aluminums

Brazing, Soldering & Flux

Cast Irons

Copper, Brass & Bronze

Metal Working

Nickels & Nickel Alloys

Overlays & Tool Steels

Spray Torches & Powders

Steels & Stainless Steels

Wear Plates, Epoxy & Putty

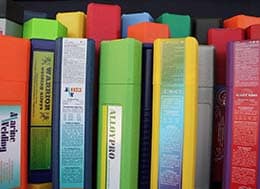

Electrode Packaging

CUSTOM PACKAGING

- Molded Plastic Containers in Four Styles and Twenty Different Colors

- Hermetically Sealed One Piece Pure Aluminum Cans.

- High Quality Cardboard Boxes.

- Vacuum Sealed Moisture Proof Foil Bags.

- Shrink Wrapping.

- Point of Purchase Displays

- Blister Cards and Clam Shell Pop Packaging.

- Bulk Tri-Wall Export Packaging and shipping cartons with warning label screened on the carton.

CUSTOM LABELING

We offer full color process custom labels on your retail package and shipping cartons. We will also package your product using your existing labels if that is your preference. All Selectrode labels and SDS sheets adhere to the new GHS requirements.